01270 753323

Cheshire Wire Erosion – Precision Machining

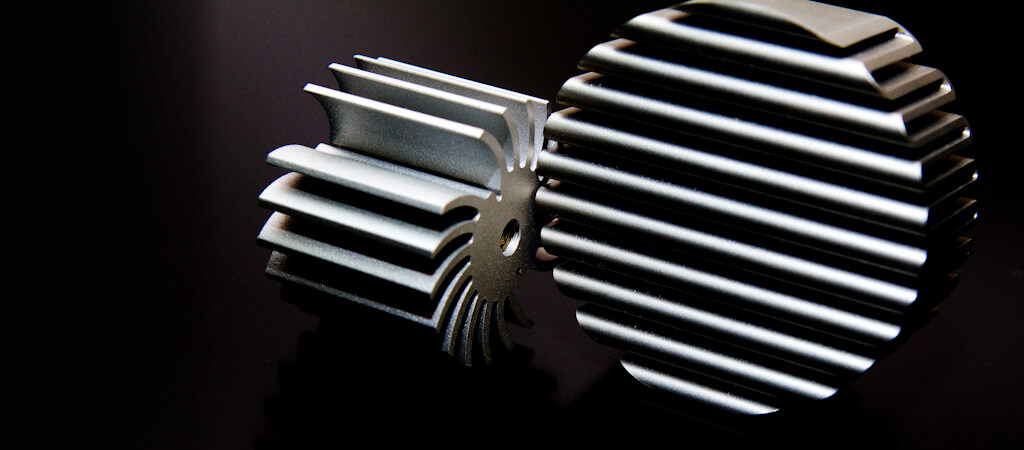

Wire EDM Machine and Conventional EDM Machines

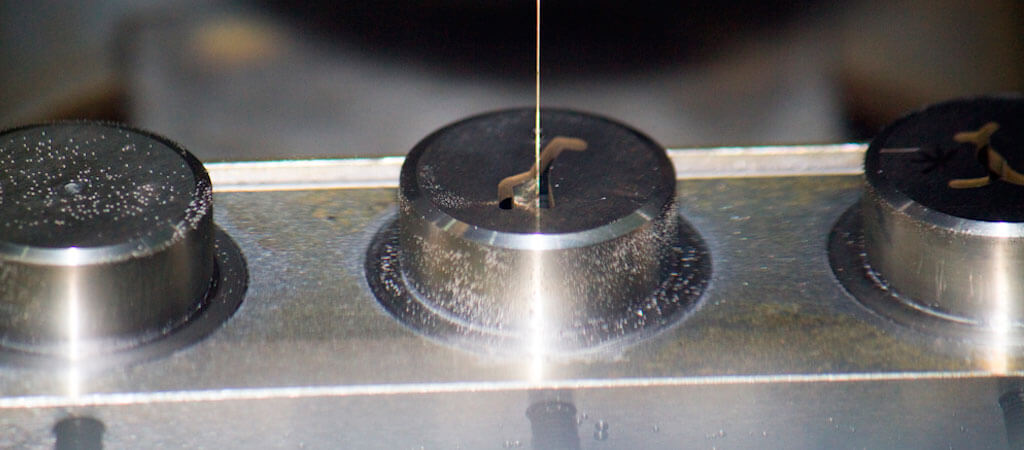

EDM stands for Electrical Discharge Machining. Essentially, this means an electrical current is passed between an electrode and another conducting surface. In doing so the conducting surface is damaged in a very small and controlled way. The damage to the receiving surface is a tiny erosion. This technique can be used to cut metals. The exact shape of the cut is determined by two methods. Conventional methods uses a pre-shaped electrode that is the opposite shape of the cut you want to achieve. This principle can be understood when righting a message to be reflected in a mirror. If you want your message to be understood from the reflection you need to scribe your message left to right rather than right to left as you would on the written page. A Wire EDM Machine, however, uses a very thin wire that is controlled by a computer and makes a series of pre-programmed movements. The Wire EDM Machine offers some advantages that are further discussed in this website.

Cutting Hard Metals using an EDM Machine

An EDM machine, put simply, is a cutting tool. An EDM machine can be used to make high precision cuts in hard metals. This is extremely advantageous over other cutting methods. Conventional methods for cutting hard metals involve a high degree of friction. A by-product of friction is the conversion of movement to heat. The principles of physics dictate that energy is never lost but converted into another form. In the case of cutting metal that conversion is to heat. When you want to make small and precise cuts to hard metals the presence of excessive and uncontrolled heat serves to warp the metal. An EDM machine does not do this.

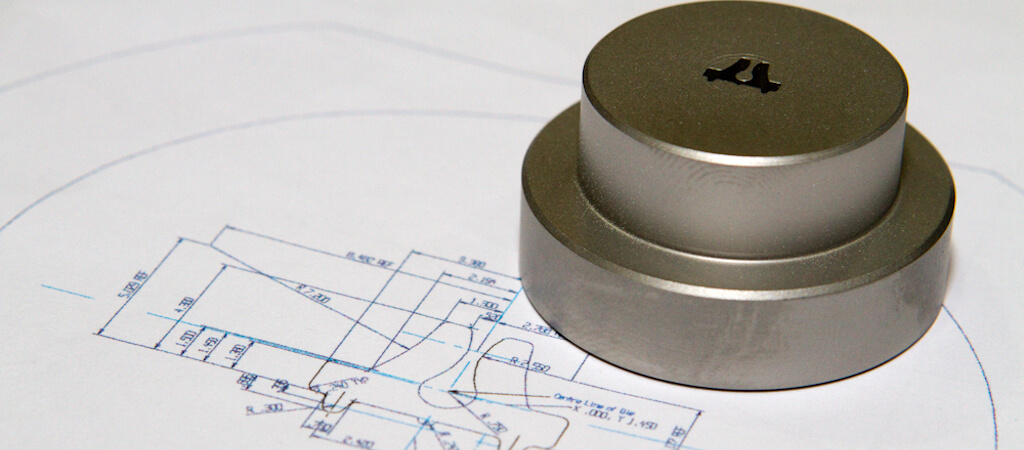

Principles of Wire EDM and CNC

A Wire EDM machine does not use a pre-shaped electrode. Therefore the wire within the Wire EDM machine must be moved to make the respective cuts. This cannot be done by hand. The wire movements must be controlled and moved with absolute precision. These movements are pre-programmed using a machining control system called CNC. The CNC system stands for Computer Numeric Control. This serves to create a numerical grid though which the movements of the wire within the Wire EDM machine can be plotted. CNC is a brilliant tool control technique and used with many other applications than Wire EDM.

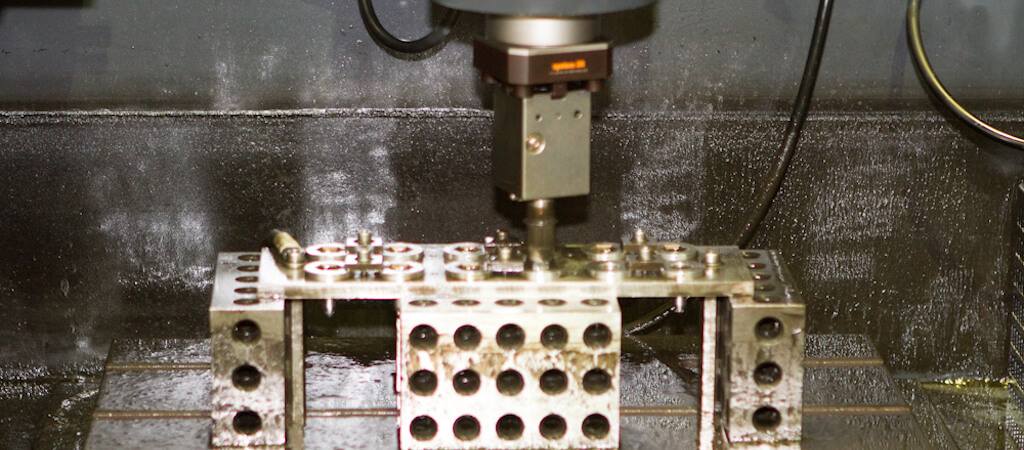

Wire EDM Machining and Cheshire Wire Erosion Ltd

Wire EDM machining is one of the many techniques employed by Cheshire Wire Erosion Ltd. Wire EDM machining is a highly specialised technique, controlled and managed by expert engineers. The team at Cheshire Wire Erosion Ltd have over 100 years of combined experience in the industry. They are your ‘go to’ experts for Wire EDM machining. As you explore this website further you will see evidence of their expertise and years of experience.

“Our goal is to continually exceed all our customer’s expectations”

Our services

Wherever engineering is involved, across a wide variety of industries including aerospace, pharmaceutical, petrochemical, food, motor, ceramic and all types of tooling. We offer an expert, knowledgeable service spanning the UK, that is competitively priced and customer focused.

From modern, purpose-built headquarters in Cheshire the very latest in high-technology machines deliver the highest of standards in Wire Electrical Discharge Machining, RAM and Fast Hole Drilling.

- Wire-Cut EDM

- Die-Sinker EDM

- Small Hole Drilling EDM