01270 753323

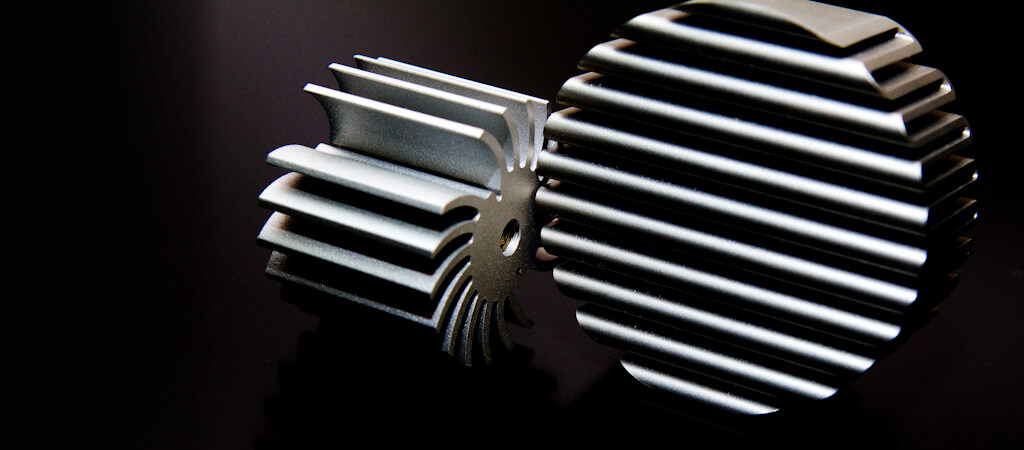

Wire EDM Machining

A Wire EDM Service that Stands Out

Cheshire Wire Erosion Ltd offers a wire EDM service that truly stands out. They believe that quality starts at the beginning. This may sound obvious but it is vital to have well established processes for understanding client needs. The wire EDM service offered at Cheshire Wire Erosion Ltd has the trademarks of professionalism, experience, creativity and delivery. The business was established 20 years ago and still retains many long term clients from those early years. This is testimony to the rapport the business endeavours to develop with their customers.

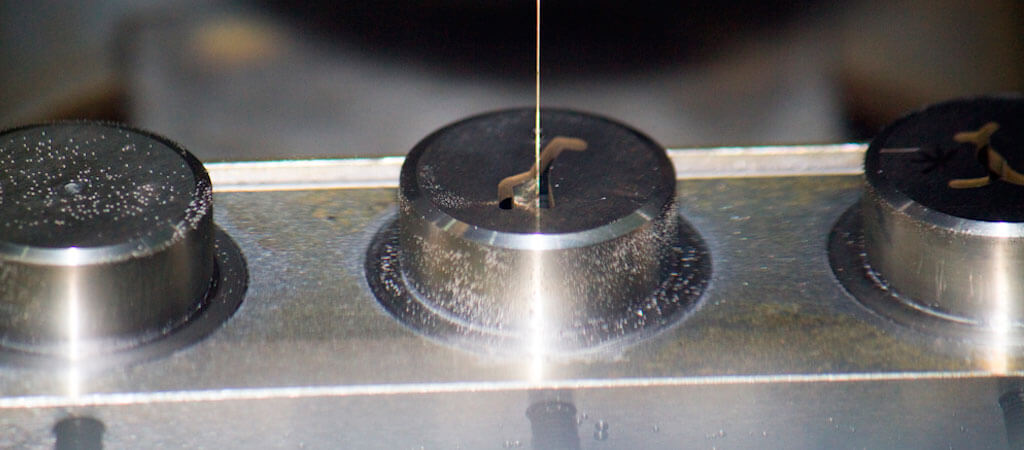

EDM Wire Cut with High Quality Wire

When making an EDM wire cut the wire serves as an electrode and suffers damage itself during the ‘cutting’ process. Consequently the wire itself can be seen as a consumable when making an EDM wire cut. This is logical when you consider other cutting tools. For example, although a saw may not perish immediately after cutting wood, it has in effect lost tiny metal particles during the cutting process which blunts the metal edge. In order for the metal edge to be useful again it has to be sharpened. This process also removes tiny particles from the metal’s surface to produce a sharp edge. Eventually though the tool can no longer be used as the metal is consumed. The process involving an EDM wire cut is a little similar. As the wire becomes damaged it is not sharpened as in the case of a metal saw but rather it is replaced by an additional length of the wire. This means the process can consume many lengths of wire.

EDM Brass Wire and Cost Efficiencies

As explained above, the EDM wire gradually becomes ‘consumed’ in the cutting process and must be continually replaced. When using high quality materials such as EDM brass wire, you are able to deliver a high frequency of sparks to effectively cut the metal before the wire is no longer useful. This is loosely analogous to how often you have to sharpen a pencil before it is no longer useful to write. Cheshire Wire Erosion Ltd use high quality EDM brass wire as part of their system as it is more efficient and leads to better results.

History of Wire Eroding

Wire eroding has its modern history in Russia in the 1940’s when scientists developed ways of using the process in a useful way. Wire eroding has further been developed over many decades to be the modern process it is today. Even though wire eroding is credited as being developed by the Russians in the early 1940’s, it was actually first observed by Joseph Priestley the British scientist in the 1700’s. He would be proud of the industry it has become today with excellent companies like Cheshire Wire Erosion Ltd.

“Our goal is to continually exceed all our customer’s expectations”

Our services

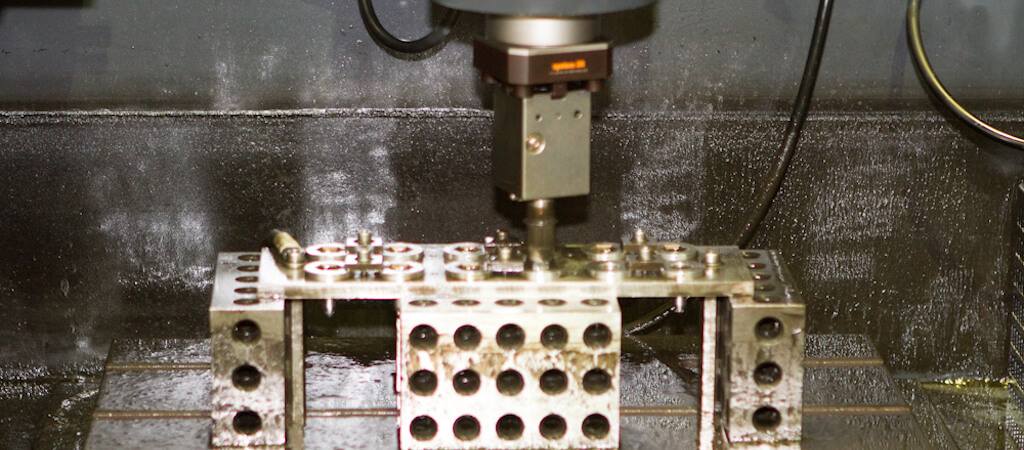

Wherever engineering is involved, across a wide variety of industries including aerospace, pharmaceutical, petrochemical, food, motor, ceramic and all types of tooling. We offer an expert, knowledgeable service spanning the UK, that is competitively priced and customer focused.

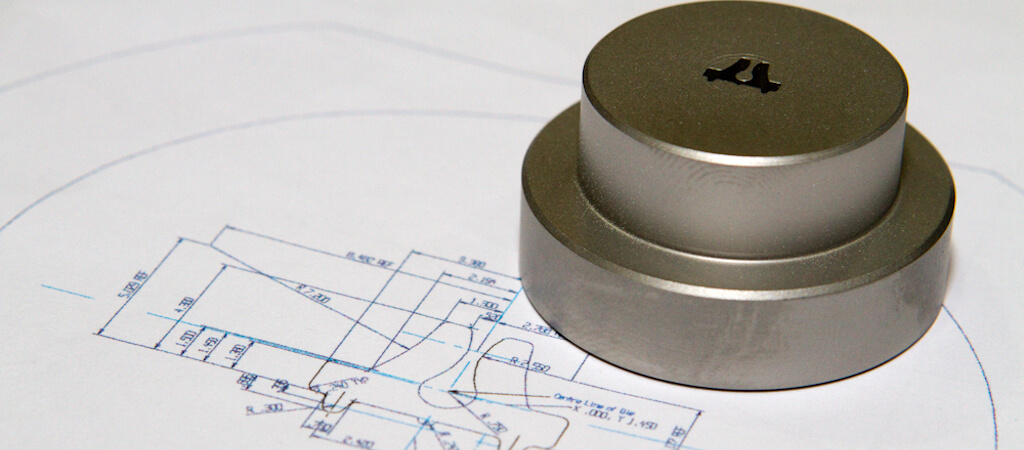

From modern, purpose-built headquarters in Cheshire the very latest in high-technology machines deliver the highest of standards in Wire Electrical Discharge Machining, RAM and Fast Hole Drilling.

- Wire-Cut EDM

- Die-Sinker EDM

- Small Hole Drilling EDM