01270 753323

Wire EDM Machining

Wire EDM Machining and Aerospace Applications

Cheshire Wire Erosion Ltd provides wire EDM machining services to a variety of sectors within the industry. This includes wire EDM machining for aerospace applications. Cheshire Wire Erosion Ltd is extremely proud to be involved in this area of industry because there is a need for components for safety critical systems. These components must meet specification and be made from high quality, durable materials. Cheshire Wire Erosion Ltd is confident in their processes of manufacture and quality control. Aerospace often sets standards that are a benchmark for others to follow. So these types of applications for EDM serve to drive up quality standards.

EDM and Horology

Horology is the science of measuring time. This also involves making time pieces. EDM is an excellent tool in cutting metal parts that can be used in time pieces. If the component parts of a clock are not within specification then the clock will not work or at best will not keep time accurately. That said, cutting the intricate and detailed metal components for a clock is no simple matter. EDM is an ideal tool for precision cutting so that these components meet their exact specification.

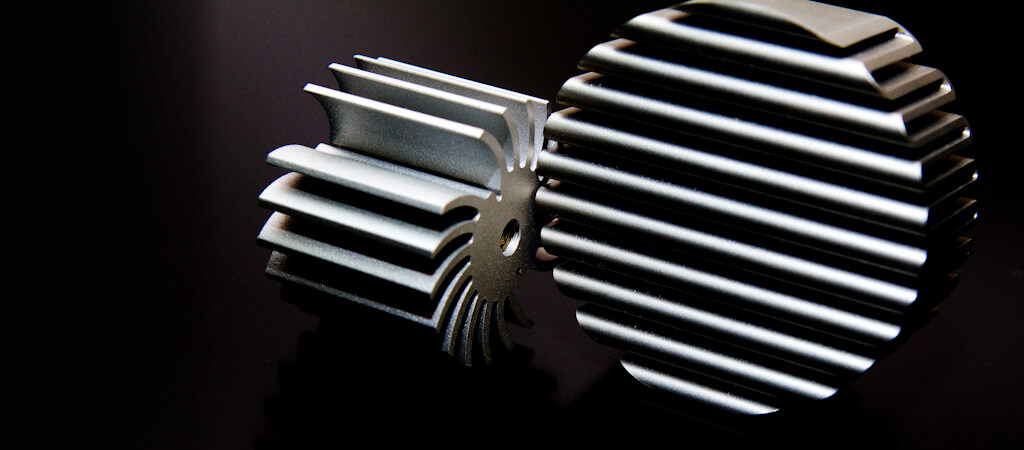

Wire EDM Machines and Precision Components

Wire EDM machines are the cutting tool to go to when there is a need for precision components. Whatever the industry, if you need components cutting that are high detail, high precision within tight tolerances, then wire EDM machines are the tool you need. Not only do you need wire EDM machines but you need expert engineers such as Cheshire Wire Erosion Ltd to program and manage the work processes involved. You can rely on the expert team at Cheshire Wire Erosion Ltd.

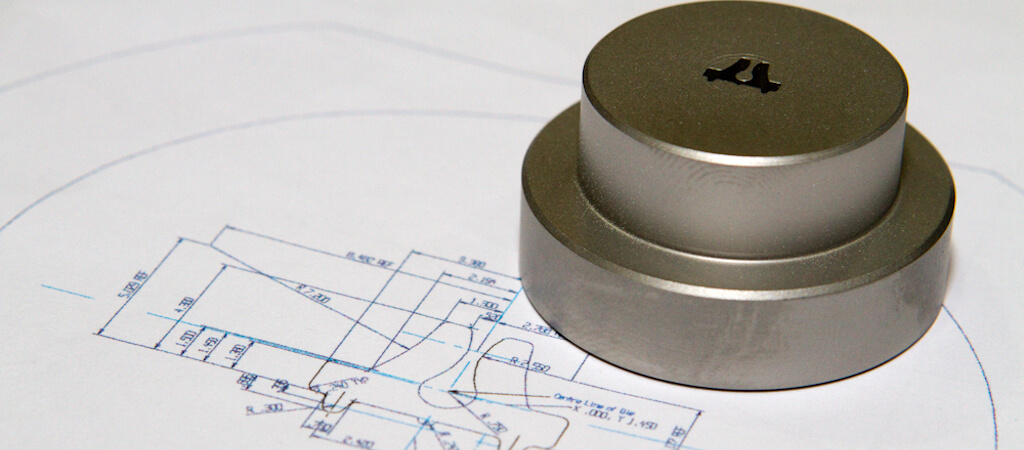

Wire Electrical Discharge Machining – Prototype to Mass Production

The team at Cheshire Wire Erosion Ltd are made up of highly experienced engineers who understand the challenge of developing prototypes and solving design and production challenges. All true engineers love design combined with technology. Wire electrical discharge machining affords the opportunity to cut and make prototype components from materials that otherwise would be impossible. Many of these materials are highly desirable because of their physical properties such as low weight and high strength. These same attributes make them extremely difficult to cut and shape in any other way than wire electrical discharge machining, particularly if the size and accuracy of the component is important. So if you are developing a prototype and need help in its production please get in touch with Cheshire Wire Erosion Ltd. They will share your passion.

“Our goal is to continually exceed all our customer’s expectations”

Our services

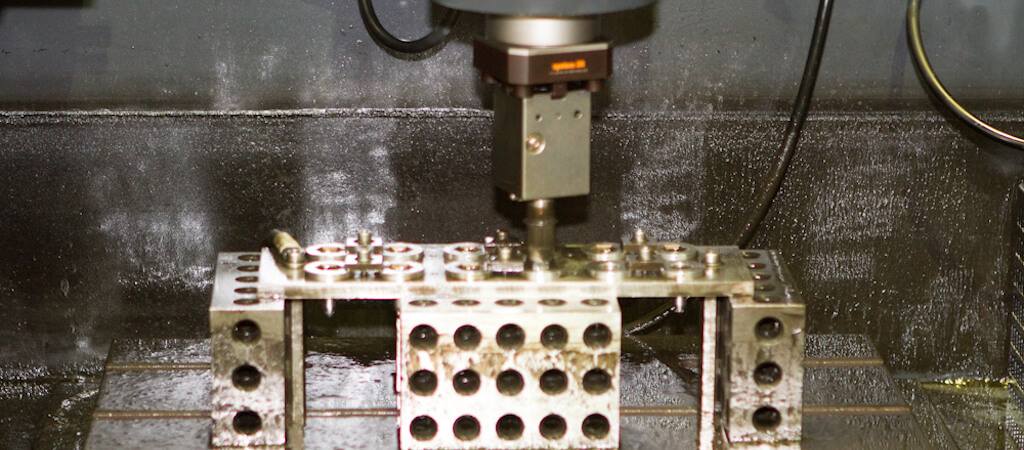

Wherever engineering is involved, across a wide variety of industries including aerospace, pharmaceutical, petrochemical, food, motor, ceramic and all types of tooling. We offer an expert, knowledgeable service spanning the UK, that is competitively priced and customer focused.

From modern, purpose-built headquarters in Cheshire the very latest in high-technology machines deliver the highest of standards in Wire Electrical Discharge Machining, RAM and Fast Hole Drilling.

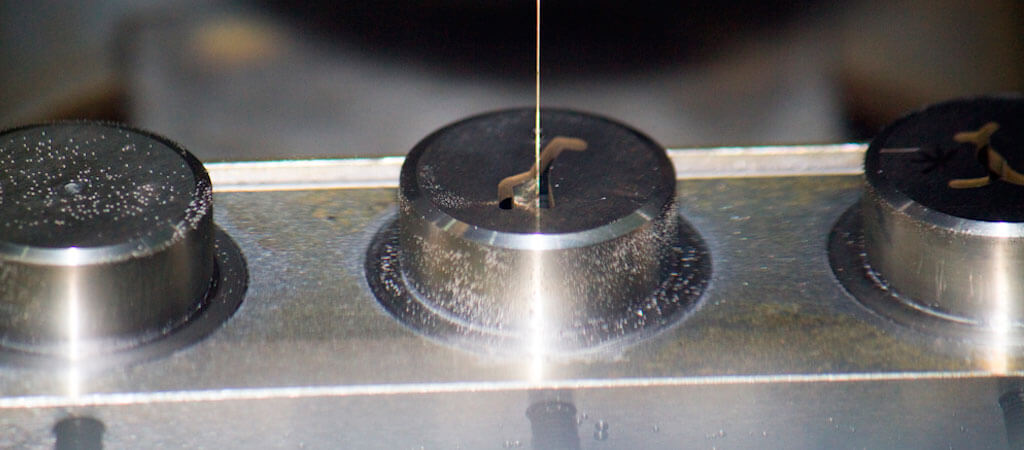

- Wire-Cut EDM

- Die-Sinker EDM

- Small Hole Drilling EDM